|

1/8 Scale King Tiger Information

Description:

The German King Tiger was the first kit produced by R/C Armory. Over three years of engineering, mold making, fixture making, and research went into the creation of the King Tiger. The tank kit is based on the late war version of the King Tiger now on display at the Patton Museum in Kentucky. The kit contains nearly 55 different injection molded parts, 3 different resin cast parts, 6 different machined aluminum parts and a precision built hull and turret. Part totals for the kit are over 165 injection molded plastic parts, 200 aluminum die cast track links with steel pins, 30 CNC machined aluminum parts, 4 resin cast parts, and over 200 miscellaneous hardware items. All detail parts are produced as separate items. If a mistake is made on a detail, a replacement part is only a phone call away and in many cases free. This allows or even encourages the builder to supper detail the kit. The results can be a remarkable. With help from the Patton Museum and hundreds of hours of research through reference material the details of the tank were recreated. Almost all of the dimensions used to develop the tank were taken from the King Tiger at the museum. Using the actual tank for dimensions avoided the chance of reproducing the dimensional errors found in some of the reference material or on the smaller scale kits. Following customer's suggestions the King Tiger kit has been continuously updated though the years. Metal tracks, improved access to the inside of the hull, and new turret details are just some of the many improvements made to the kit since its introduction.

|  |

The hull and turret is constructed from a lightweight 6mm thick gray PVC plastic sheet called Sentra. The lightweight characteristic of this plastic comes from its high density foam core sandwiched between two smooth surfaces. The plastic sheet is cut using a CNC router system to ensure high dimensional accuracy of each part. The cut pieces are positioned and glued together in production fixtures to form very rigid structures. This process ensures that every hull and turret are dimensionally correct and that all components are correctly located and aligned. Access into the hull is through the removable front plate that contains the driver and radio operator's hatches, the large turret bearing, and the removable engine deck.

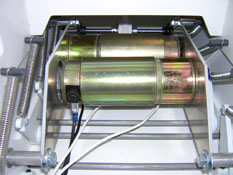

The parts for the drive train are made from injection molded plastic where low stress levels are involved and aluminum or steel where higher stresses are found. Road wheels, idler wheels, and the hub of the drive sprocket are injection molded from very tough polystyrene. The suspension arms, idler arms, tracks, track pins, road wheel shafts, drive sprocket shaft, and drive sprocket tooth rings are aluminum or steel. Each track is powered by an industrial quality all ball bearing electric gear motor. Power from each gearmotor is transferred to tracks first through a 1/4 pitch roller chains then to the final drive reduction gears located in the housing which supports the drive sprocket. The main drive system for the tracks is sold as an option and can be installed at any time.

|  |

The turret rotates on a 12" ring ball bearing that comes installed on the inside of the deck plate. This large bearing allows for smooth low friction rotation of the turret. An optional gear drive system powered by an electric gear motor is used to rotate the turret. By removing the turret the center of the hull can be accessed. The turret also features an aluminum pivot that supports the gun for elevation and a frame that is used to hold the optional gun elevation gear motor. The turret drive options can be and installed at any time even after construction is complete.

Features:

Kit contains plastic injection molded, cast aluminum, steel, and resin cast parts along with a preassembled hull and turret. Track links, road wheels, and the hub of the drive sprockets are made from injection molded polysterene. The suspension arms, idler arms, track pins, road wheel shafts, and drive sprocket tooth rings are aluminum or steel. Each track is powered by an electric gearmotor. Power from the gearmotors is transferred to the drive sprockets through a custom designed drive system.

Construction:

The average modeler should be able to assemble the King Tiger kit in about 100 hours. Some modelers have built the kit in less time but most spend extra time adding many of the fine details found on tanks during combat. Expect to spend an additional 25 hours for painting. Only basic hand tools are required to assemble the tank. Items such as paint, batteries, battery charger, radio equipment (4 channel ), and speed controllers are not included with the kit. The retail price for a basic kit is $1,750.00. The options for the basic kit are as follows.

Pictures:

Specifications:

Price..........................................................................$1,875.00

Length Overall..............................................................49.70 Inches

Length Hull..................................................................35.50 Inches

Width..........................................................................18.50 Inches

Height..........................................................................14.875 Inches

Weight (Empty).............................................................45 lbs

Weight (Complete).........................................................65 lbs

Options:

Drive System (Motors, Chains, Sprockets, and Mounting Hardware)....................$475.00

Turret Drive (Motors, Pinion Gear, Drive Plate, and Motor Mount)........................$135.00

Gun Elevation Drive (Motor, and Hardware)........................................................$70.00

Electronic Dual Speed Controller With Channel Mixing.......................................$135.00

Shipping.......................................................................................................$105.00 (within U.S.)

|